From Prototype to Production: Unlocking the Power of 3D Printing in Manufacturing

Additive manufacturing, known as 3D Printing, has countless uses. It assists in manufacturing many designs and even tools to help bolster the products your company offers. It is the go-to method for most small-scale manufacturing industries nowadays. Moreover, 3D Printing allows for producing products without paying for tooling. But if you are wondering how, it benefits the manufacturing industries, you’ve come to the right place.

This blog explores how 3D printing is transforming product development, from rapid prototyping in early stages to full-scale, low-volume production of functional parts.

Benefits of 3D Printing in Manufacturing

In general, 3D Printing is advantageous to small industries for creating small-scale products, components for larger assemblies, and prototypes. Besides, 3D Printing is suitable for most industries because the in-house production of many parts, tools, and small-scale products helps diversify a company’s portfolio. Although 3D Printing may not replace current plastic manufacturing techniques, its versatility as a production technique puts it at the forefront for most engineering companies to prototype and test a product’s functionality.

Similarly, 3D printers are relatively cheap and more accessible than other plastic manufacturing techniques that provide similar outputs, thus allowing users of all levels around the world to benefit from the manufacturing process.

An increasingly relevant example is the use of 3D printing in industries such as aerospace, automotive, and healthcare, where custom parts manufacturing and rapid prototyping significantly reduce time to market and development costs.

As design validation progresses, companies are increasingly using the same or upgraded machines to print final-use parts, functional jigs, fixtures, and even low-volume product batches, without switching to traditional manufacturing.

Overview of 3D Printing Technologies

To summarize, there are various 3D printer methods such as Selective Laser Sintering (SLS), Stereolithography (SLA), and Fused Deposition Modelling (FDM). Each of these methods comes with its benefits and limitations.

Fused Deposition Modelling (FDM)

Typically, FDM needs support material and is usually hollow. FDM printing has a higher chance of interruption during the print process, such as clogged filaments and layer adhesion issues. Although it can print complex geometry, supports are a must to have a successful output.

Stereolithography (SLA)

There are three parts to this method: print, clean, and cure. This method is typically robust and provides a more stable output without the worries of filaments clogging during the printing. Besides, integrating supports can yield complex geometry.

Selective Laser Sintering (SLS)

There are two parts to this method: print and cool down. On the contrary, this method does not require printing support because the powder used itself works as a support, hence allowing the printing of complex geometry without any external supports.

However, all of the above processes can be time-consuming as each print is completed layer by layer. Nonetheless, it is faster than conventional prototyping techniques with typical lead times of two to six weeks.

Cutting Down Costs

In summary, the most cost-effective and readily available of the three techniques above is FDM printing. FDM printers are excellent for printing items smaller or up to the same size as the printer. These printers are relatively cost-effective and typically range from £100 to over £1000, depending on features and build size.

In comparison, SLA and SLS have similar technologies, but the results are distinguishably different. Compared to FDM, SLA printing is currently the choice for many engineering companies as it creates high-resolution products. Furthermore, a significant degree of testing can be conducted on the printed parts compared to FDM printing.

SLS is now gaining traction in desktop and prosumer-grade machines. It remains the most accurate and durable among the three for functional prototyping and low-volume production, especially for end-use parts.

Space, Portability, and Accessibility

Opting for a smaller-sized printer is a viable decision as the printer itself does not occupy much space. Although 3D printers come with different configurations, some keep the workspace stationary while the head moves. In others, the head is stationary while the workspace moves.

Usually, the average size of an FDM printer is around 20cm x 20cm x 20cm and is provided by brands like Bambu Lab, Prusa, and Creality. These small printers are significantly smaller than industrial machinery and have the added benefit of portability.

In flexible work environments, such as remote or hybrid setups, small 3D printers can be easily moved, set up, and used at home or in satellite offices for continued prototyping and development.

Bridging the Gap: From Prototype to Production

One of the most transformative aspects of 3D printing is the ability to shift from rapid prototyping to full-scale production, without changing tooling, machines, or processes. This seamless transition allows businesses to:

- Validate designs quickly and iterate faster

- Launch small production runs without upfront investment in moulds or dies

- Personalize products on demand

- Reduce waste and storage needs by printing only what’s needed

By scaling up with multiple machines, adopting more advanced materials, or upgrading to SLS and industrial-grade printers, manufacturers can achieve consistent quality and production efficiency.

Flexibility in Production

When using a 3D printer, modifying a product is just a few clicks away. Consequently, it makes prototype designing more accessible than ever by reducing the time from months to days. If you decide to cycle between different products during production, all that is required is a few clicks on your personal computer or the printer itself.

Press start and you are good to go. No tools or attachments are changed or added for a change in the product. After printing, just remove the previous part produced, select the new design you want to print, and start the printing process. Therefore, reducing production time.

Smart Features and Remote Access

Newer printers come with a mobile application to access the printer through your mobile phone, as long as both the mobile phone and printer are connected to a working internet connection. Therefore, it allows you to check in on the print process from wherever you are and whenever you want.

Modern printers such as those from Bambu Lab, Prusa MK4, and Creality K1 include smart sensors, AI-assisted failure detection, and automated calibration for reliable and hands-off printing.

CAD Software Compatibility

Mostly, all printers require 3D CAD parts in an STL or OBJ file format. Most 3D CAD software can export to STL, so no matter what designing tool you or your company uses, you will be able to export your parts to STL for 3D printing.

Additional slicing software is required to split the STL design into layers converted into G-codes. G-codes are used by the printer to print the parts at your desired location on the build plate; slicing software is typically free.

RELATED READ: Fusion 360 vs SolidWorks: Which CAD Software Is Right for You?

Popular 3D Slicing Software

| Software | Operating System | Purchase | Skill Required |

|---|---|---|---|

| Bambu Studio | Windows & Mac | Free | Beginner to Advanced |

| Cura | Windows, Mac & Linux | Free | Beginner to Advanced |

| PrusaSlicer | Windows, Mac & Linux | Free | Beginner to Advanced |

| OrcaSlicer | Windows, Mac & Linux | Free | Intermediate to Advanced |

| MatterControl | Windows, Mac & Linux | Free | Beginner to Advanced |

| SuperSlicer | Windows, Mac & Linux | Free | Intermediate to Advanced |

User-Friendly Interface

Designing a new product can be time-consuming. However, once the design is completed, you’re just a few clicks away. JOA Designs can create outstanding designs for you. Doing the rest is as easy as it can get. The printer itself and the slicing software have straightforward user interfaces and require little to no experience to operate.

Similarly, a 3D slicer works as a translator for the printer by creating a tool path based on the STL-file content and deducing the infill percentages for the 3D printer. A good 3D slicer guarantees superior results even with mediocre printers; finding the ideal slicer settings is the key.

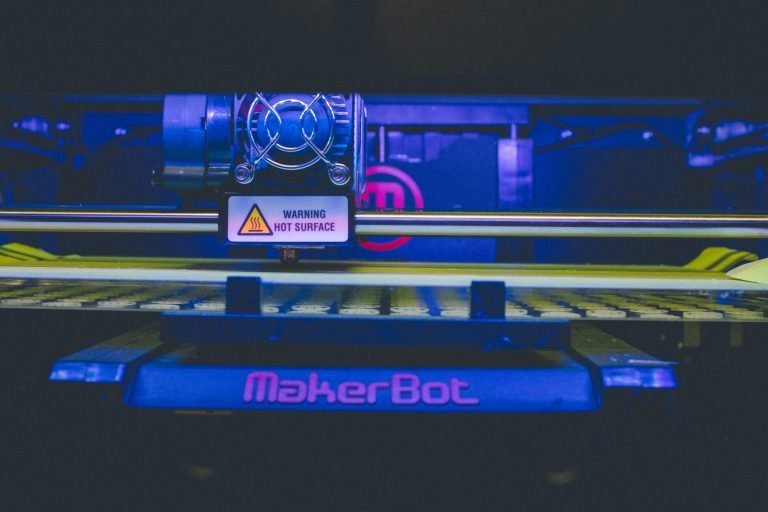

Safety Considerations

While there aren’t many hazards involved in operating a 3D printer, there are a few to be noted. The print nozzle can heat up to 230ºC so that the filament plastic can reach its melting point; fumes are common. Therefore, when printing is in progress, keep the room ventilated, particularly for ABS filament.

Beyond Product Manufacturing

3D printers can be utilized in an industrial setting to ease specific production processes, which require some special custom tools to facilitate the procedures. By using a 3D printer, custom parts can be created to reduce downtime and increase production efficiency.

Low Production and Infrastructure Costs

Compared to the printer, the plastic itself is not so expensive, and it is also the primary raw material used in 3D printing. The replenishment process is possible at meagre prices, resulting in low production costs. Depending upon the printing material quality, the filament ranges anywhere between £15–£25 per kg.

A 3D printer requires no more than an ordinary 120-volt power outlet to operate. In some situations, regarding closed environments, ventilation fans may be necessary.

Getting Started with 3D Printing

New to 3D printing? Explore online platforms such as Printables.com, Thangs, or Thingiverse to find useful files for various gadgets to print to help around the house or office.

If you’re looking to develop a new printer, reach out to us, and we can help you achieve your goals efficiently. JOA Designs is experienced in 3D printing technology, and we have designed many 3D printers to use in-house.

Budget-Friendly to Professional 3D Printers

| 3D Printer | Build Volume (mm) | Market Price (£) |

|---|---|---|

| Bambu Lab P1P | 256 x 256 x 256 | 399 |

| Creality K1 | 220 x 220 x 250 | 379 |

| Anycubic Kobra 2 | 220 x 220 x 250 | 209 |

| Prusa MK4 | 250 x 210 x 220 | 699 |

| Bambu Lab X1 Carbon | 256 x 256 x 256 | 1059 |

| Formlabs Form 4 | 200 x 125 x 210 | 3999 |

| Raise3D Pro3 | 300 x 300 x 300 | 5099 |

| Formlabs Fuse 1+ 30W | 165 x 165 x 300 | 7999 |

| Ultimaker S7 | 330 x 240 x 300 | 5500 |

| Markforged FX20 | 525 x 400 x 400 | 39900 |

Conclusion

3D printing has evolved from a prototyping tool into a powerful solution for agile, customized manufacturing. Whether you are creating one-off prototypes or scaling up for small batch production, the flexibility, speed, and affordability of 3D printing can help you stay competitive.

If you’re ready to turn your concept into reality or scale your production affordably, contact us at JOA Designs. We’re here to help you every step of the way.

See how we automated the design process for a 3D printers’ manufacturer using DriveWorks.