Mechanical Design Automation with DriveWorks: Boosting Efficiency and Customisation in Engineering

With changing business dynamics, industries are even more focused on identifying routine tasks that can be eliminated to streamline the industrial process and achieve perfection. Mechanical Design Automation is the most promising solution as this approach possesses excellent potential to increase efficiency and optimise cost. Moreover, this inevitable change will give industries a competitive advantage, elevate performance, and leverage growth.

DriveWorks: A Smarter Approach to Automation

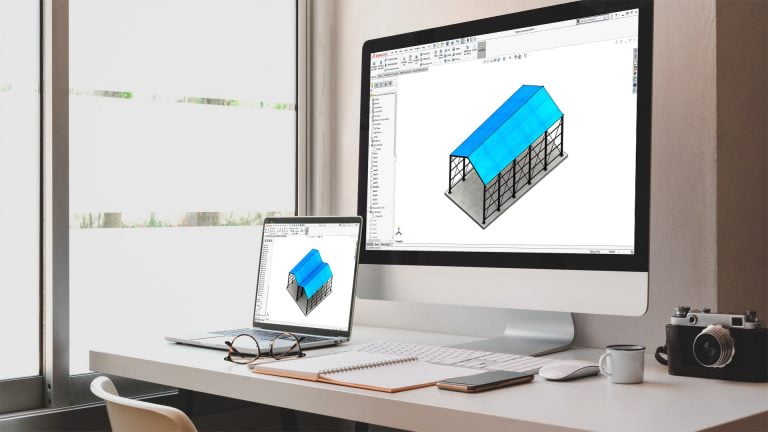

DriveWorks is a holistic mechanical design automation solution for SolidWorks. It removes redundant tasks through automation, which allows engineers to better utilise their time. Therefore, they can redirect their skills and knowledge to improving and developing products. DriveWorks applications encompass a broad range of jobs in engineering firms, such as:

- Creating bills of materials as required

- Moving analytical data to proposal designs

- Transferring the ordering material from the design software to the accounting software

Once a firm undertakes mechanical design automation and incorporates it into its routines, there is a definite reduction in errors and less wastage of time. Ultimately, this has a noticeable impact on the firm’s overall efficiency.

Key Benefits of Mechanical Design Automation

DriveWorks provides mechanical design automation tools that can help your company step up its game and eliminate inefficiencies. Engineering firms can automate various jobs like generating bills and sales proposals with 3D graphical rendering and design models swiftly. With minimal risk of errors and significant time savings, engineers can focus on developing new products. These innovations lead to higher quality production and increased sales performance.

Automation in Engineering and Design Firms

Every manufacturer implements mechanical design automation differently. However, they all target the same outcomes: lower human intervention, error-free processes, and eliminating redundant activities. As a result, design automation has a remarkable impact on efficiency and profitability.

Depending upon a firm’s individual goals, design automation has numerous benefits in addition to cost savings and productivity improvements. Some of them include:

Eliminating Errors in Repetitive Tasks

SolidWorks can eliminate the majority of repetitive tasks through automation, significantly reducing costly human errors. From generating bills of materials to partial completion of designs, mechanical design automation addresses common pain points. Moreover, bi-directional data transfer between CAD, ERP systems, PDM/PLMs, and Microsoft Office ensures seamless and accurate task execution.

Generating Immediate Proposals

With streamlined collaboration between departments, proposals can be generated much faster and tailored to the buyer’s needs. These proposals include graphical representations and bills of materials to accurately estimate manufacturing costs. Automating this process helps companies close more sales and accelerate revenue generation.

Increasing Customisation and Reducing Turnaround Time

Sales teams can quickly locate data and deliver customised proposals based on previous projects and saved presets. Mechanical design automation simplifies the deal-closing process, shortens turnaround time, and results in satisfied customers and repeat business.

How DriveWorks Enables Custom Design Automation Workflows

DriveWorks is built for configurability. Engineers and sales teams can define custom rules, workflows, and interfaces to match product complexity and customer requirements. The system adapts to:

- Specific product logic and variations

- Unique quoting and design rules

- Custom form layouts and input experiences

- Visual 3D previews for end-user interaction

Whether using DriveWorks Solo for mid-level automation or upgrading to DriveWorks Pro for advanced configurability, the platform supports tailored workflows that reflect real business processes.

The Industrial Impact of Mechanical Design Automation

Mechanical design automation has a tremendous positive impact on the mechanical industry. Enterprises benefit from automation by reducing the time and resources spent identifying and correcting errors. This leads to increased staff efficiency and significantly improved ROI.

The mechanical industry deals with many moving parts and designs, most of them similar. With mechanical design automation, slight modifications can be made quickly without wasting time or money on failed trials. Most mechanical firms face a high volume of repetitive tasks requiring only slight adjustments per customer. Automating those processes allows engineers to focus on innovation instead of repetition.

SolidWorks, paired with DriveWorks, allows companies to fully customise automation tools to meet exact needs using the latest design technology.

Real-World Application: A Custom Conveyor System Example

Imagine a company that builds custom conveyor systems. Without automation, engineers manually update each CAD drawing, bill of materials, and proposal for every unique configuration. With DriveWorks:

- The sales team inputs customer requirements via a custom form

- DriveWorks generates a 3D model and an accurate quote in minutes

- Engineering gets an error-free, ready-to-manufacture design

This drastically cuts proposal time, reduces errors, and accelerates delivery, leading to higher win rates and lower engineering costs.

Implementing Mechanical Design Automation with DriveWorks

Implementing mechanical design automation follows a standard project life cycle:

Scoping

It begins with a thorough analysis of how your firm operates, its workflows, and the tasks best suited for automation.

Solution

Based on the analysis, a tailored automation strategy is designed to fit your company’s specific goals and structure.

Walkthrough

A guided, step-by-step transition ensures smooth adoption. This phase helps identify gaps and ensures all departments are prepared.

Implementation

DriveWorks software offers flexible, scalable solutions for customising programs to match industry-specific workflows. It connects design automation with existing ERP, CRM, and CAD systems for end-to-end efficiency.

DriveWorks Solo vs Pro: Choosing the Right Fit

- DriveWorks Solo is ideal for small teams automating repetitive tasks in SolidWorks.

- DriveWorks Pro is designed for full-scale automation across sales, engineering, and manufacturing.

Each version supports scalability and offers the foundation for deeper rule-building and integration, depending on company size and complexity.

RELATED READ: DriveWorks Xpress vs Solo vs Pro: Key Differences Explained

Supporting Your Transition to Automation

Consultation

Consultation on hardware, software, and system compatibility is essential. Proper guidance ensures smooth deployment.

Training

Training and onboarding materials, whether in-person or online, equip teams to use automation effectively. DriveWorks offers extensive tutorials, documentation, and support resources.

Support

Automation has a direct impact on production and sales, so technical support is critical. JOA Designs provides ongoing assistance and troubleshooting to ensure your systems perform at peak capacity.

Take the next step, streamline your processes, empower your teams, and transform your engineering output with our free DriveWorks sample and Mechanical Design Automation using DriveWorks.